Vibration Testing

Vibrations occur during transport due to external factors, such as environmental influences (wind, vehicle engines, equipment) or internal sources (engines within the device itself). These vibrations can be significantly amplified by resonance, a phenomenon where an object absorbs more energy at a specific frequency, causing it to vibrate more intensely. This can be harmful to both packaged products and devices.

Navigate to:

→ Overview tests

→ Specifications testing machines

→ Standards

→ Reasons to test

Types of vibration tests

An overview of vibration tests that Sebert Group carries out for you:

Sinus sweep triltest

A sinus sweep test involves applying sinusoidal vibrations within a defined frequency range, with a predetermined amplitude and sweep rate (Hz per minute). A practical analogy is playing a piano, where one moves stepwise from low notes (low frequencies) to high notes (high frequencies).

Objective: Identify the resonance frequencies of a product, component, or packaging. Resonance occurs when a product naturally vibrates at specific frequencies, potentially causing increased stress and damage.

Application: Once resonance frequencies are identified, additional endurance tests, such as a sinus dwell test, are typically conducted. During these tests, the product is exposed to specific resonance frequencies for extended periods. This simulates real-world conditions where resonances can lead to phenomena such as scuffing or material fatigue.

Sinus Dwell triltest

A sinus dwell test applies a fixed frequency and amplitude over a specified duration.

Applications:

- Hazardous material packaging: For example, the DOT test under ASTM D 999, evaluates packaging under mechanical stress.

- Maritime industry: This test is used to assess the performance and functionality of products in marine environments. For instance, the IEC 60945 standard requires a product to withstand a 30 Hz sinusoidal vibration with a 0.7 g amplitude for two hours, ensuring full functionality during and after testing.

Random vibration testing is primarily used for transport simulations and other complex vibration scenarios.

- Mechanism: Unlike sinus tests (which focus on a single frequency), random tests apply multiple frequencies simultaneously across a broad spectrum with fluctuating amplitudes. This simulates the complex vibration profiles experienced by products during transportation or use in vehicles.

- Applications:

- Transport simulation: Based on standards such as ASTM, ISTA, IEC, NEN, or ISO, or field measurements. This replicates the vibration behavior of trucks, trains, airplanes, and ships.

- Specific Standards:

- Railway products: Must comply with IEC 61373, simulating railway environments.

- Vehicles: Standards like SAE J1455 and MIL-STD-810 describe stress on electronic equipment in vehicles and military applications.

- Electronic products: Must meet IEC 6721 requirements, simulating vibration in specific phases.

- Flexibility: Random vibration tests are widely used not only for transport simulations but also for other scenarios requiring realistic and complex stress profiles.

Standards

Product standards

- MIL-STD-810: Environmental tests, including vibration and shock, specifically for military equipment.

- MIL-STD-167: Mechanical vibration standard for shipboard equipment.

- AECTP 400 (NATO): Mechanical Environmental Tests.

IEC standards (International Electrotechnical Commission)

- IEC 60068-2-6: Environmental testing – Vibration tests with sinusoidal vibrations.

- IEC 60068-2-64: Vibration testing with random (stochastic) frequencies.

- IEC 61373: Vibration and shock tests for railway applications.

- IEC 61373: Railway Applications – Rolling Stock Equipment.

- NEN-EN 50125-3: Railway Applications – Environmental conditions for equipment – Part 3: Equipment for signaling and telecommunications.

- IEC 60721: Classification of environmental conditions to which equipment may be exposed:

- IEC 60721-3-2: Classification of environmental conditions during transport.

- IEC 60721-3-3: Classification of environmental conditions during stationary use.

- IEC 60721-3-4: Classification of environmental conditions during mobile use.

- IEC 60721-3-5: Classification of environmental conditions during use in maritime environments.

- IEC 60721-4-1: Transport phase.

- IEC 60721-4-3: Usage phase.

- IEC 60721-4-4: Installation phase.

- IEC 60721-4-5: On-site repair phase (field repair).

- SAE J1455: Environmental testing procedures for vehicle components.

- SAE J1211: Testing environments for electrical and electronic equipment in vehicles.

- UNECE R100 Regulations: Ensures that electric vehicles and their energy storage systems can withstand mechanical stresses that may occur during normal use, including transport and operational conditions.

- ISO 12405-3: Covers test methods for electric vehicle batteries, including vibration tests.

- UN 38.3: Tests for the transport of lithium batteries.

Classification Societies

Testing standards for vibration and shock in maritime and offshore applications.

Standards for vibration testing of equipment for maritime and industrial environments.

Guidelines for vibration and shock testing for ship and offshore installations.

Packaging standards

- STM D4169: Standard practice for performance testing of packaged products during the entire distribution cycle.

- ASTM D999: Test method for sinusoidal vibration testing of packaged products during transport.

- ASTM D4728: Test methods for random vibration testing of packaged products during transport.

- ISTA 1 Series: Basic tests, including vibration tests.

- ISTA 2 Series: Advanced combination tests for distribution simulation.

- ISTA 3 Series: Tests for specific packaging configurations and products.

- ISTA 6 Series: Tests for e-commerce-specific packaging (e.g., for Amazon).

E-Commerce specific standards:

- Amazon ISTA 6-Amazon.com

- Test methods for products and packaging shipped via Amazon.

- FedEx packaging lab protocols

- Tests designed to ensure safe delivery through FedEx shipping channels.

- ISO 4180: Simulating the physical and mechanical stresses to which packaging is subjected in a realistic logistics chain.

- ISO 13355: Packaging – Test methods for vibrations in transport.

- ISO 8318: Packaging – Investigation of vibrations during transport.

- ISO 2247: Packaging – Shock and vibration testing for industrial packaging.

Accreditation

The Sebert Group is accredited by the Dutch Accreditation Council (RvA), part of European Accreditation (EA) and ILAC. Tests performed in our ISO 17025-accredited laboratory are globally recognized, unlike ISO 9001 or ISTA laboratories. ISO/IEC 17025 requires qualified staff, calibrated equipment, and validated methods, ensuring independent, reliable, and high-quality test results. Our scope can be found on the RvA website (registration number L540).

Benefits of the ILAC•MRA Logo

Reports with the ILAC•MRA logo ensure global acceptance, including in the EU, USA, Japan, and beyond.

This eliminates the need for redundant testing and bureaucratic processes, supporting the free trade principle: "One tested product accepted everywhere."

Accredited Report for Vibration Testing

Do you need an accredited report for vibration testing? Tests must fall within the following scope:

- Test type: Sinusoidal vibration

- Conditions: Calibrated and controlled

Specifications:

- Maximum acceleration: 1,120 m/s²

- Maximum velocity: 1.8 m/s

- Maximum displacement: 60 mm

- Frequency range: 1-2,000 Hz

- Test type: Random vibration

- Conditions: Calibrated and controlled

Specifications:

- Maximum acceleration: 1,120 m/s²

- Maximum velocity: 1.8 m/s

- Maximum displacement: 60 mm

- Frequency range: 1-2,000 Hz

Vibration testing

There are various types of vibration tests used to assess the durability, reliability, and performance of products and packaging. The most common types include sinusoidal vibrations (sinus), random vibrations, sinus-on-random, and several other variants.

Each test is applied depending on the specific requirements and objectives. The vibration levels (amplitude) and frequency ranges are tailored to the standards or specific application requirements.

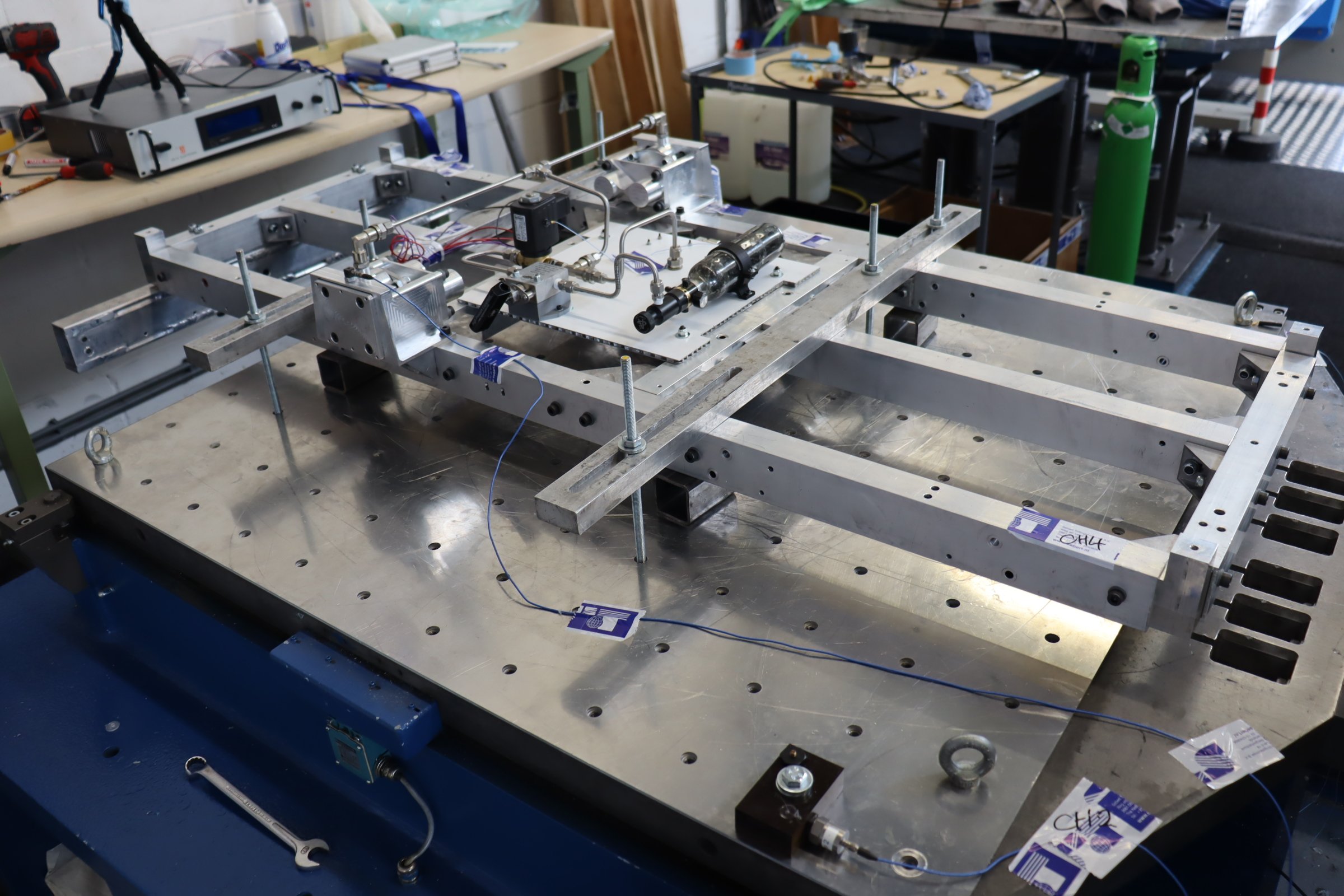

Specifications of Testing Machines in Our Facility

With our two hydraulic vibration tables from Lansmont, we can perform various types of vibration tests in compliance with standards. These tables can also replicate real-time vibration profiles combined with extreme climates and/or low pressure. For example:

- Truck Vibration Simulation Test combined with +40°C and 90% humidity.

- Aircraft Vibration Simulation Test combined with a low pressure of 250 mbar and a temperature of -40°C.

Specifications:

- Maximum test weight: 2,700 kg

- Maximum acceleration: 10 g

- Test direction: Vertical

- Tabletop dimensions: 1,500 x 1,500 mm

- Frequency range: 0.1 Hz - 300 Hz

- Displacement: 60 mm (peak-to-peak)

- Temperature range: -40°C to 70°C

- Climate range: 5°C to 40°C and 98% humidity

- Low pressure: Supported

- Vibration profiles: Sinus dwell, Sinus sweep, Random

The Sebert Group operates two electric vibration tables from Tira, capable of generating extreme accelerations of up to 112 g continuously, in both vertical and horizontal directions. Vibration tests can be conducted up to 3,000 Hz. Due to their precision, these tables can handle complex vibration forms such as random-on-sine-on-random, as specified in AECTP 400 and MIL-STD 810.

Specifications:

- Maximum test weight: 1,300 kg

- Maximum acceleration: 112 g continuous

- Test direction: Vertical and horizontal

- Tabletop dimensions: 1,200 x 1,200 mm

- Frequency range: 1 Hz - 3,000 Hz

- Displacement: 60 mm (peak-to-peak)

- Vibration profiles: Sinus dwell, Sinus sweep, Random, Random-on-Sine, Sine-on-Random, and Random-on-Sine-on-Random

6 reasons why companies choose to perform these climate and temperature tests.

- Equipment: Vibration testing is often conducted to verify whether machines or equipment can withstand the vibrations they may encounter during operation or transport.

- Structural Integrity: Testing prevents potential defects or damage caused by vibrations.

- Validation: During the development of new products, vibration tests are used to ensure that the design meets the necessary requirements.

- Optimization: By analyzing vibration behavior, designers can make improvements to optimize performance.

- Transportation: Vibration tests that simulate transport conditions are often conducted to ensure that a product arrives damage-free after transit.

- Vibration Analysis: For existing installations or machinery, vibration analysis can help identify the sources of problems, such as imbalance, wear, or loose components.

- Many industries have specific vibration standards (e.g., ISO standards). Vibration testing is necessary to meet these standards and obtain certifications.

- Subjecting products to vibrations helps determine how long they will last under various conditions and how reliable they are.

Do you have any questions?

Want to learn more about our testing methods or specific tests? Our experts are here to help with any inquiries you might have. Reach out today and find out how the Sebert Group can support you in delivering unmatched quality and reliability.