IP Protection Testing

Testing effects of dust, rain (Water), and solid object intrusion (Including body parts like hands and fingers)

Conducting IP protection tests at The Sebert Group provides an accurate and reliable way to evaluate the protection levels of your products against dust, water, and other external factors.

Navigate to:

→ Overview tests

→ Specifications testing machines

→ Standards

→ Reasons for testing

→ All IPX-tests

Types of IP protection testing:

| First digit | Description | Test Method |

|---|---|---|

| 0 | No protection | No test required |

| 1 | Objects > 50 mm | Ball test (50 mm diameter) |

| 2 | Objects > 12.5 mm | Cylinder test (12.5 mm diameter) |

| 3 | Objects > 2.5 mm | Wire test (2.5 mm diameter) |

| 4 | Objects > 1 mm | Wire test (1 mm diameter) |

| First digit | Description | Test Method |

|---|---|---|

| 5 | Limited dust ingress | Sealed chamber, under-pressure test |

| 6 | Fully dust-tight | Sealed chamber, no ingress allowed |

| Second Digit | Description | Test Method |

|---|---|---|

| 0 | No protection | No test required |

| 1 | Vertical water drips | 10-minute drip test |

| 2 | Water dripping at angles up to 15° | Inclined drip test |

| 3 | Sprays up to 60° from vertical | Spray nozzle, 0.7 l/min |

| 4 | Water from all directions | Spray nozzle, 10 l/min |

| 5 | Low-pressure waterjets | Hose test, 12.5 l/min at 3m |

| 6 | High-pressure waterjets | Hose test, 100 l/min at 3m |

| 7 | Temporary immersion (up to 1m depth) | 30-minute immersion |

| 8 | Continuous immersion (over 1m depth) | Depth-specific immersion |

| 9K | High-pressure and high-temperature jets | 100-bar, 80°C spray test |

Standards

IEC 60529

- Title: Degrees of Protection Provided by Enclosures (IP Code)

- Content: The foundational standard for IP classifications, outlining testing methods for protection against solid object ingress and liquids.

EN 60529

- European version of IEC 60529.

- Applicable across Europe for the same IP classification tests.

ISO 20653

- Title: Road Vehicles – Degrees of Protection (IP Code) – Protection of Electrical Equipment Against Foreign Objects, Water, and Access.

- Content: Specifically designed for vehicles and their components.

IEC 62262

- Title: Degrees of Protection Provided by Enclosures for Electrical Equipment Against External Mechanical Impacts (IK Code).

- Content: Defines IK ratings for mechanical impact resistance.

ISO 12944

- Title: Paints and Varnishes – Corrosion Protection of Steel Structures by Protective Paint Systems.

- Content: Focused on corrosion protection for enclosures.

IEC 60068-2 Series

- Title: Environmental Testing – Various Parts (Vibration, Shock, and More).

- Content: Environmental-related tests such as vibrations and shocks that complement IP tests.

EN 62208

- Title: Empty Enclosures for Low-Voltage Switchgear and Control gear Assemblies – General Requirements.

- Content: Test methods for enclosures that also require IP protection.

Medical devices

- IEC 60601-1: Guidelines for the safety and performance of medical equipment, including sealing and IP-related aspects.

Automotive

- ISO 16750-4: Test procedures for environmental conditions of vehicle electronic components, including water and dust resistance.

Industrial machinery

- IEC 61439: Standard for low-voltage switchgear and control gear assemblies, with guidelines for IP testing.

Consumer electronics

- IEC 62368-1: Safety requirements for audio, video, IT, and communication technology equipment.

ASTM D6653

- Title: Standard Test Method for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method.

- Content: Test methods for packaging seals exposed to low pressure and water infiltration.

ISTA Series

- International packaging standards, addressing not only shock and vibration resistance but also water resistance.

UL 50 / UL 50E

- Title: Enclosures for Electrical Equipment.

- Content: Guidelines for IP-related protection and robustness, specifically for the North American market.

MIL-STD-810H

- Title: Environmental Engineering Considerations and Laboratory Tests.

- Content: Testing procedures for military equipment, including water and dust resistance.

Combination tests for higher IP codes

For complex products, such as electronics or industrial equipment, combinations of the above tests are often performed. For example:

- IP65: Protection against dust (5) and water jets (6).

- IP68: Protection against dust (6) and prolonged immersion in water (8).

Additional IP testing

In addition to standard tests, Sebert Trillingstechniek can perform additional tests to validate the IP classification:

- Mechanical impact testing (IK coding): Assessing the physical robustness of housings against impact.

- Thermal testing: Check whether the IP rating is maintained in extreme temperatures.

- Fatigue Testing: Repeated exposure to dust or water to assess the life of seals.

Specifications of our testing equipment

(IPX1, IPX2, IPX3, IPX4, IPX5, IPX6, and IPX7)

Specifications

- Test chamber dimensions:

- Internal: 500 x 500 x 500 mm

- External: Unlimited space

- Water flow rate: 1 – 100 l/m

- Temperature range: 10 – 55°C

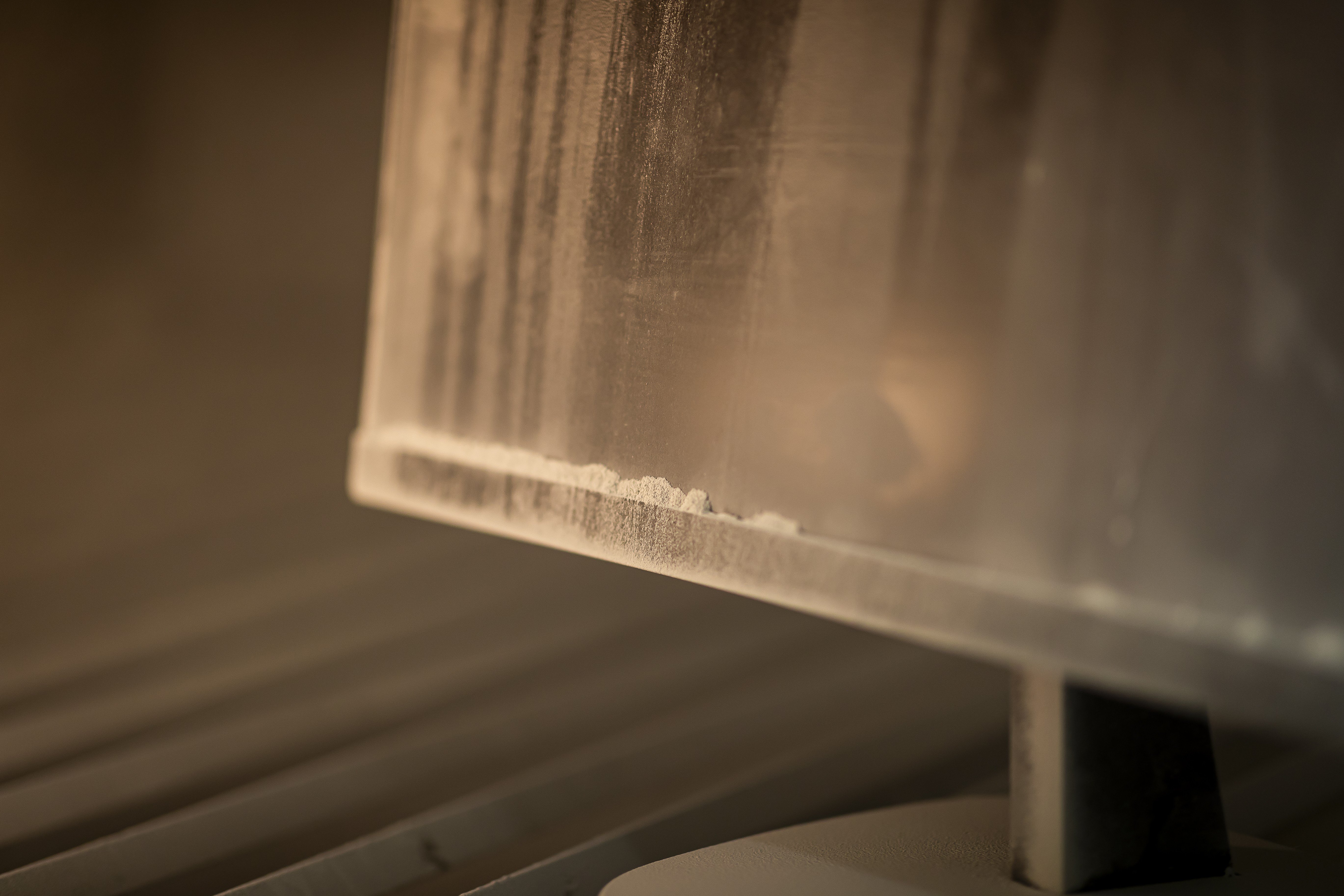

(IP5X and IP6X)

Specifications

- Test item dimensions: 1700 x 1160 x 1500 mm

- Dust concentration range: 2 – 4 kg/m³

- Airflow: 2 – 3 m/s

(IP1X, IP2X, IP3X, IP4X)

Specifications

- Test methods:

- Ball (50 mm diameter)

- Cylinder (12.5 mm diameter for finger simulation)

- Wire (2.5 mm and 1 mm diameters)

This are the key reasons why IP testing is invaluable:

The IEC 60529 standard defines the IP (Ingress Protection) code, which specifies how well a product is protected against:

- Solid particles (e.g., dust and sand)

- Liquids (e.g., water in various forms, from splashes to full immersion)

Testing at The Sebert Group enables you to achieve an official protection level, such as IP65, IP67, or IP68.

- Wear protection: Testing helps verify if a product can withstand daily exposure to dust and water.

- Extended lifespan: Properly tested products are more durable, even in challenging environments.

- Many industries, such as electronics, medical equipment, and automotive, require specific IP classifications.

- Testing with a professional partner like The Sebert Group ensures your product complies with international standards.

- Electronics: Devices like smartphones, tablets, and sensors used in humid or dusty conditions often require a high IP rating, such as IP68.

- Industrial Applications: Machinery and equipment exposed to harsh conditions often need IP65 or higher.

A well-tested IP classification reduces the risk of defects caused by water or dust damage, leading to:

- Lower warranty costs

- Improved customer satisfaction

- Accurate Simulations: Sebert’s specialized equipment replicates realistic environmental factors, ensuring thorough product testing.

- Quality Reporting: Receive detailed measurement data and an official test report, useful for internal quality assurance or external certification.

- An IP-certified product demonstrates reliability and quality, offering a significant selling point in markets where robustness and durability are prioritized.

Electronic devices and enclosures are exposed to moisture in various environments. Whether it's household appliances, industrial equipment, or medical technology, moisture infiltration can significantly affect a product’s performance and lifespan. The IPX1-test is one of the basic levels of the Ingress Protection (IP) rating and assesses whether a product can withstand vertically dripping water.

The IPX2-testis an important Ingress Protection (IP) test designed to assess whether a product can withstand dripping water at a 15° angle. This test may be relevant for products such as household appliances used in humid environments or medical equipment that needs to resist condensation.

The IPX3-testis a crucial Ingress Protection (IP) test that evaluates whether a product can withstand spraying water at angles of up to 60°. This test is suitable for products such as outdoor lighting exposed to rain, industrial control panels operating in humid environments, or automotive electronics subject to splashing water.

The IPX4-test is an important Ingress Protection (IP) test that determines whether a product can withstand splashing water from all directions. This test may be conducted for products such as outdoor lighting, control panels, vehicle electronics, and household appliances that may occasionally come into contact with water.

The IPX5-test is a standardized method used to determine whether a product is protected against direct low-pressure water jets. This is especially relevant for products exposed to rain, cleaning processes, or splashing water in industrial or marine environments. This test can be applied to products that need to withstand powerful water jets.

The IPX6-test is a critical testing method used to determine whether a product is protected against powerful high-pressure water jets. This test is suitable for products that need to withstand harsh weather conditions and intensive use.

For products that may accidentally end up in water, the IPX7-test offers protection against damage from temporary immersion.

For products designed for long-term underwater use, the IPX8-test provides assurance. This test evaluates whether a product remains waterproof during continuous immersion, typically under specified pressure and time conditions.

The IPX9-test is the highest standard for water protection, assessing whether a product can withstand powerful high-pressure, high-temperature water jets. This is relevant for vehicles, industrial equipment, or other applications in extreme environments.