Can your product or housing withstand a bump?

Choose certainty, choose:

✓ Lower transportation expenses

✓ Improved product certification.

✓ Measuring = knowing

✓ Experts & Experience

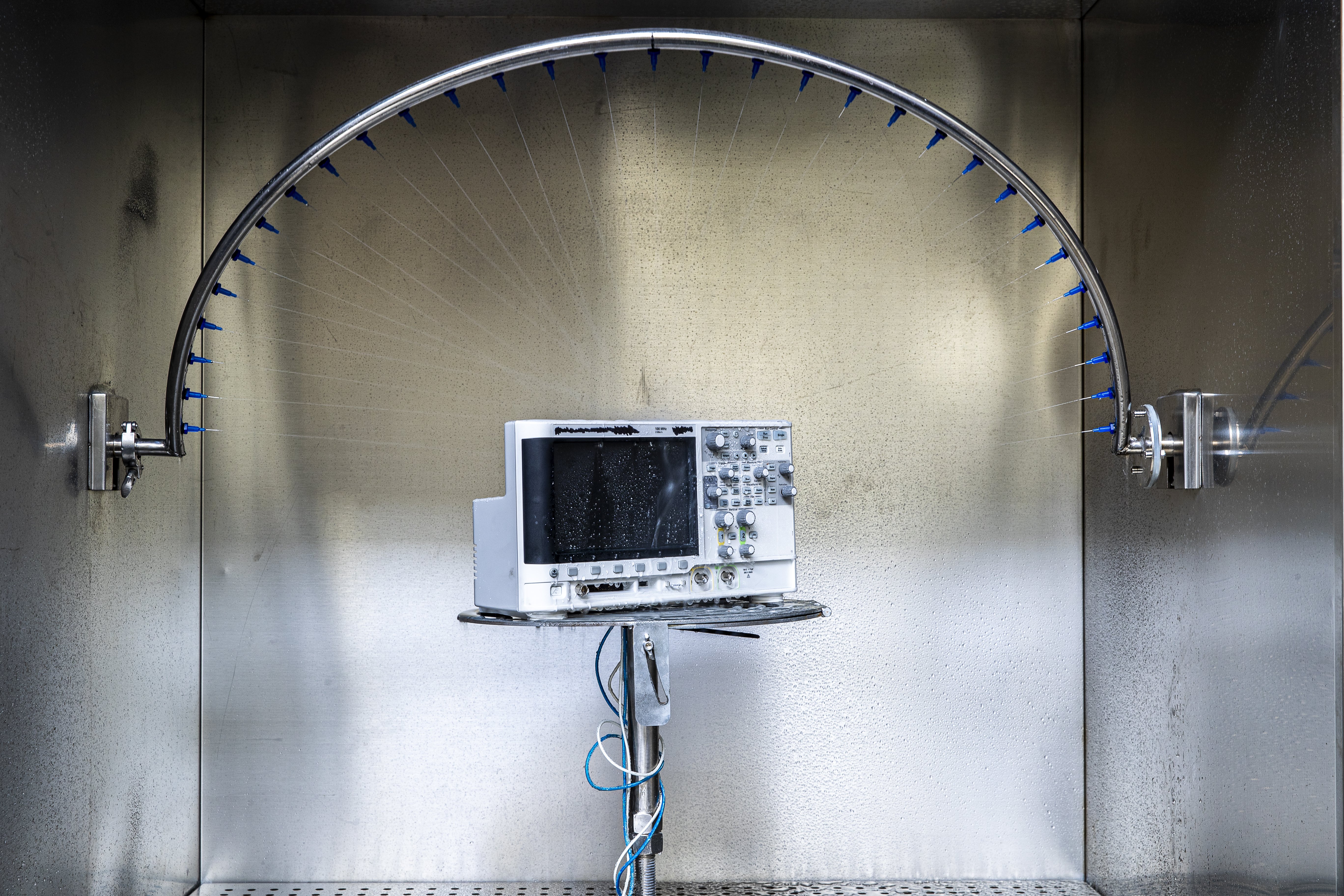

✓ According IEC 60529

✓ Proven simulations

✓ Quality assurance

Combine for a complete evaluation

At Sebert Group, by combining multiple tests, we can provide a comprehensive overview of your product's performance under various conditions.

A selection of our tests:

Does your product need to meet strict requirements?

But, you run into problems when:

- You're not sure if it will withstand all circumstances.

- You're missing hard test data for tenders or standardisation.

- You don't want an unexpected outage to occur for the customer.

The risk of not performing practical tests:

High risks for financial, legal, and reputational damage. It only takes a defective part or an untested situation to incur one of all three of these risks.

That's why we simulate to test the practice in a lab. This way, you'll never be caught off guard.

Product failure is not an option, choose certainty.

Your product needs to be able to withstand the 'real' world. From vibrations in a defence vehicle and temperature changes in an aircraft. From corrosion at sea to impact absorption during transport.

This means your product must not fail in these environments. How do you ensure this? With our lab tests specifically designed to simulate all the environments your product comes into contact with.

Have your product tested in realistic conditions. Ideal for applications in defence, aerospace, marine, and transportation.

At Sebert Group, it's not about ticking off a standard, but about building reliable projects.

How is my product tested?

We do this under the most relevant or demanding conditions. Think of:

✓ Vibration, shock, and impact load

✓ Moisture, corrosion, and temperature fluctuations

✓ Waterproof, dustproof, and impact-resistant

We combine tests into a program that simulates your practice. This way, you discover early on where your product needs to be reinforced. Or that it's ready to go to market.

We are ISO/IEC 17025 accredited. You can count on independence, reliability, and thorough reporting.

Flexible testing solutions

Our testing procedures are flexible and are fully tailored to your specific needs. The duration of the tests can vary from a few days to several weeks, depending on the complexity and the desired climate conditions.

Under realistic transport and storage conditions, we test:

- Components

- Equipment

- Complete systems

This way, you can be confident that your product can withstand the real world.

What can you expect after your contact request?

- We start with an introduction: in this, we discuss your application and the requirements (standards, tenders, customer wishes).

- We will provide you with a proposal: a clear test plan with costs, timing, and a customised approach.

- Agreed? Then the execution begins, and we start with testing in our lab.

- Finally, the results & advice: a complete report with measurement data and recommendations.

After the results are known, we actively think along with you about material selection, design improvement, and validation. So you can go for that certification or tender.