Demonstrably meet NATO requirements? Yes!

Choose certainty, choose:

✓ Reduced risk of misinterpretation

✓ Faster international acceptance

✓ No re-inspections or delaysen

Brief alignment prevents re-examination and delays later in the process.

✓ USA: MIL-STD 810

✓ NATO: AECTP 400

✓ UK: DEF STAN 00-035

✓ ISO/IEC 17025

Accredited defence testing

Defence requirements don't automatically translate into the correct test setup. Standards allow for interpretation, while projects actually require clarity and predictability.

Within our accreditation, we perform, among other things:

Vibration test

Sine and random vibration tests to simulate loads during deployment, transport, and operational use. Performed within a controlled and recognised test environment according to defence and NATO standards.

Shock, bump and impact test

Shock and bump tests under defined conditions to verify sudden mechanical loads, such as those occurring during handling, deployment, or incidents.

Drop test

Drop tests to assess the robustness and functional integrity of products when dropped during transport, handling, or operational conditions.

"Defence testing at Sebert Group is focused on acceptance into the project, not just on achieving a test result."

What does our accreditation mean for your project in concrete terms?

Our accreditation determines whether test results are directly accepted within defence programmes or whether additional questions, interpretations, or re-examinations will follow.

Sebert Trillingstechniek has been ISO/IEC 17025 accredited for defence testing since 2012 according to MIL-STD-810. This has recently been expanded with AECTP 400 (NATO) and DEF STAN 00-035 (UK).

Therefore, we are authorised to perform NATO-related vibration, shock, drop, and impact tests under controlled and recognised conditions.

For your project, this means:

- test results that are immediately usable

- reports that stand up to audits and tenders

- less reliance on additional interpretations

Contributing to test setup and acceptance

In defence projects, delays rarely arise from testing but rather from ambiguity. What exactly is being demonstrated? According to which interpretation? And who accepts the result? That's why we look beyond just the test question.

We think along about, among other things:

- the correct choice and interpretation of standards

- the relationship between design, load, and test level

- the structure of a test that leads to acceptance, not to further questions

This way, testing becomes a controlled step in the project, instead of an uncertain moment afterward.

Flexible testing solutions

Your defence project requires a test setup that aligns with the intended use, transport, and storage. Therefore, our testing procedure is tailored to the project goal, the standard context, and the required acceptance level.

The duration of testing varies from a few days to several weeks, depending on the load profile, test setup, and the required verification and repetition cycle. This makes it possible to perform both targeted verifications and complete qualification paths.

What can you expect after your application?

- We start with an introduction: in this, we discuss your application and the requirements (standards, tenders, customer wishes).

- We will provide you with a proposal: a clear test plan with costs, timing, and a customised approach.

- Agreed? Then the execution begins, and we start with testing in our lab.

- Finally, the results & advice: a complete report with measurement data and recommendations.

After the results are known, we actively think along with you about material selection, design improvement, and validation. So you can go for that certification or tender.

Applications

Military and Defence

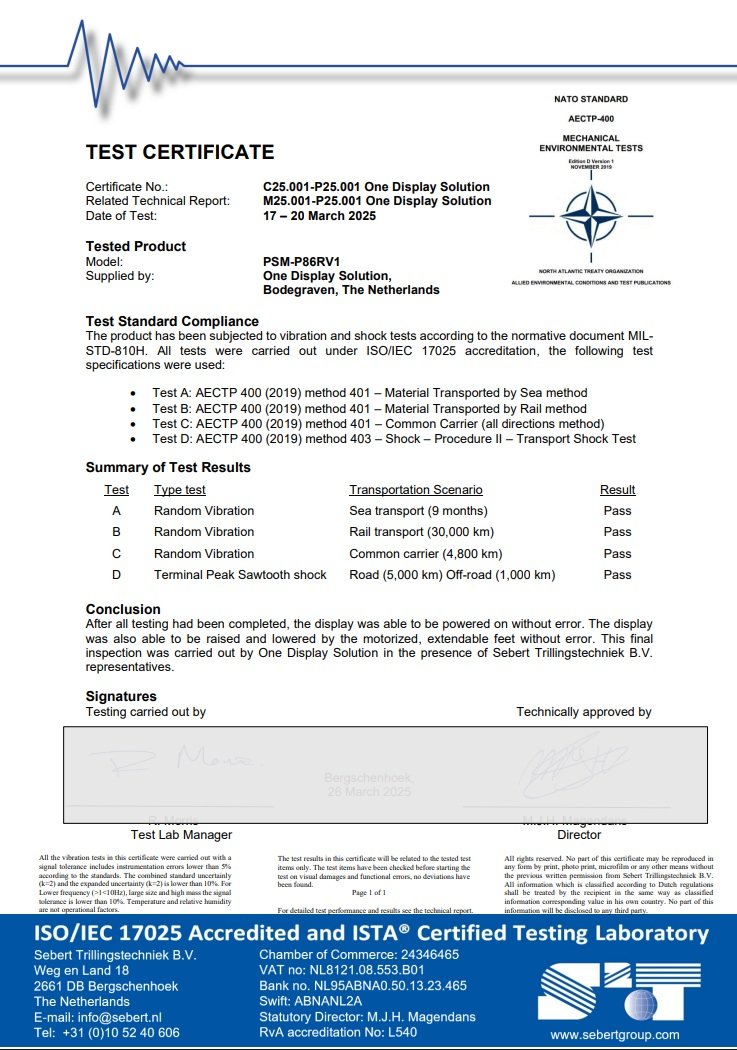

Offers optimal protection for sensitive electronics and equipment in military vehicles, aircraft, and naval vessels. The system has been extensively tested in the Sebert Test Lab and fully complies with NATO standard AECTP 400, method 401.

Proven performance includes:

- Simulation of 9 months of sea transport

- 30,000 km vibration simulation for train transport

- 4,800 km vibration simulation for truck transport

- 5,000 km of road and 1,000 km of off-road shock simulation

The test certificate provides a clear overview, and our test report offers a detailed insight into the tests performed. View the full test report here:

MIL-STD 810/AECTP 400 testrapport

Aerospace

Ensures the safety and reliability of avionics and other essential systems in both aircraft and spacecraft under severe vibration and shock conditions.