Acoustic Tube Mounts (ATM)

Acoustic Tube Mounts, also known as ATMs, are used to isolate structural noise and vibrations in pipelines. Vibrations and structural noise from equipment (diesel engines, pumps, etc.) are transmitted through the connected pipelines, even when rubber bellows or hoses are used.

Why choose Acoustic Tube Mounts from The Sebert Group

The improvement in airborne noise levels (in ship accommodations) achieved with ATMs includes a reduction of approximately 10 dB at low frequencies (around 100 Hz) and 25–40 dB at higher frequencies (around 500 Hz) or even more, depending on the construction.

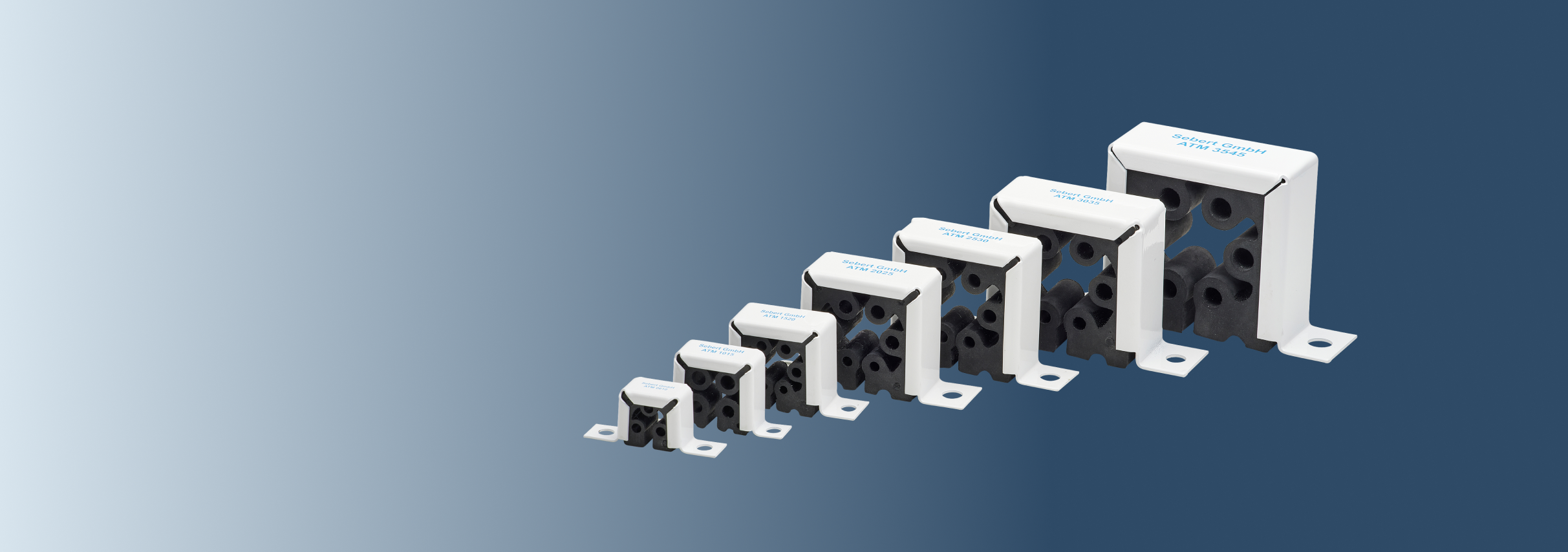

ATMs are available in various shapes. The standard is rectangular, but they can also be provided as round pipe clamps with a slightly larger diameter than the pipeline normally requires. Other designs are also possible upon consultation.

The quantity depends on the pipeline layout and the pipeline's position relative to the ship's structure. The Sebert Group advises on the optimal layout (placement of ATMs) and attachment to the ship's structure. ATMs can also be used on the equipment itself, further reducing vibrations in the ship.

Sebert Group ATM's

The transmission occurs via the liquid in the pipeline and through the walls of the bellows or hose. Pipelines can significantly reduce or completely negate the effectiveness of a well-designed resilient mounting. Rubber bellows and hoses often fail to work effectively because the pipeline on both sides of the bellows or hose lacks sufficient stiffness in all directions.

This can be resolved by creating rigid foundations, but this is very costly. ATMs are primarily used for hydraulic pipelines, pipelines prone to cavitation, and pipelines experiencing high vibration levels due to pressure pulsations.

Specific features

- A few models cover a wide range of pipe sizes.

- Optimal damping of structure-borne noise and vibrations.

- Proven design.

- No additional mounting parts required.

- Product complies with all known shock resistance requirements.

- Minimal installation procedures.

- Non-magnetic materials.

- Oil, grease, and solvent-resistant polymer.

- Resistant to high temperatures.

- The above benefits reduce costs for parts and logistics.

Performance measurement

Based on structural noise measurements of equipment, a noise prognosis was made for sleeping quarters onboard, directly above an auxiliary engine room.

In the graph:

- The top line represents the structural noise level from previous measurements.

- The line below represents the structural noise level achieved by The Sebert Group using ATMs (10–20 dB lower).

- The second-lowest line represents the calculated airborne noise level (total 62 dBA 20μPa).

- The lowest line represents the achieved airborne noise level (45–48 dBA).

This represents a reduction of approximately 16 dB! Simply put, it is 5 times quieter.

Files

Do you have any questions?

Want to learn more about our testing methods or specific tests? Our experts are here to help with any inquiries you might have. Reach out today and find out how the Sebert Group can support you in delivering unmatched quality and reliability.